LIFE SCIENCE

Filtration Solutions for Lifescience

Pharmaceutical companies and those involved in “Lifescience” have gone beyond traditional business models and are operating at worldwide scale nowadays. The challenges for the production of new medicines and active substances are requiring increased research and more strict cooperation with suppliers to design and realize new production lines and more flexible and efficient new equipment. BEA Technologies is aware of these new demands and put its knowledge at disposal to reach the quality and safety levels required by current regulations. The filtration technologies proposed by us are finalized to reach the highest quality – price rate for sterilization and clarifications of products, active substances for pharmaceutical use and utilities. BEA Technologies provides solutions for the microfiltration of liquids and compressed gases specifically designed for the needs of companies involved in Life-sciences: Pharmaceutical, Medical, Cosmetic operations.

PHARMACEUTICAL USE

- Water and water for injection (PW – HPW – WFI)

- Injectable solutions

- Depirogenetion

- Syrups and products for oral use

- Ophtalmic solutions

- Active ingredients (API e HPAPI) and fine powder retention.

- Air sterilization and steam filtration for fermentation

- Treatment of additives and solvents

- Point of use filtration

- Dialysis

- Bioburden reduction

- Sterilization of fluids and solutions

- Purification of Gas for medical use (compressed air and nitrogen)

COSMETIC

- Creme/Mousse

- Gel

- Aerosol

SINGLE USE

- Active ingredients (API e HPAPI)

- Capsules

- Materials of production in compliance to USP requirements

- Certification (UE) 10/2011

- USP water for injection

- Materials BSE/TSE free e “Animal-free”

- Halal

- PED e ATEX for vessels and housings

- Tests in internal laboratory and at customer’s site to correctly size the filtration systems and optimize the filtration process

- Technical support for Validation with development of IQ, PQ, OQ protocols adapted to the customer’s processes and assistance to preparation of “regulatory support files”

- Worldwide technical assistance

- Customer service available to answer to any commercial or technical enquiry

BEAPURE - ANIMAL FREE

BEA Technologies has developed specific filter elements targeted to guarantee the highest quality of products in most critical applications of Bio-pharmaceutical industry. These filter elements are marketed under “BEAPURE” trade mark, which incorporate the use of high purity materials delivered by a carefully controlled “Supply chain”.

BEAPURE is designed to guarantee maximum safety for final patients:

- Materials used in production which are characterized to be BSE/TSE free and have “Animal-free” statement.

- Production materials in compliance with regulations coming from carefully controlled “Supply chain”.

• Regular and repeated quality controls in BEA internal laboratory and analysis of extractables carried out in external laboratories.

• Production in highly controlled environment (Clean room) to guarantee accurate protection from external contamination.

Traceability and careful marking of production materials to guarantee the “Quality chain” from manufacturer to final user.

Compliance to most recently issued European, USP and FDA regulations and codes.

VALEX-POTENT modular system for API - HIGH POTENT products.

VALEX-POTENT is a system specifically dedicated for critical filtrations and purification of HPAPI (Highly Potent Active Pharma Ingredients) and of other different potentially hazardous-toxic substances utilized in pharmaceutical production processes. The heart of the system is a filter element able to retain contaminant particles, bacteria and other microorganisms and to adsorb the most fine traces of contamination.

VALEX-POTENT is a modular system designed in compliance with the requirement of “Double containment” and designed to be adapted to the different applications and quantity of product to be purified.

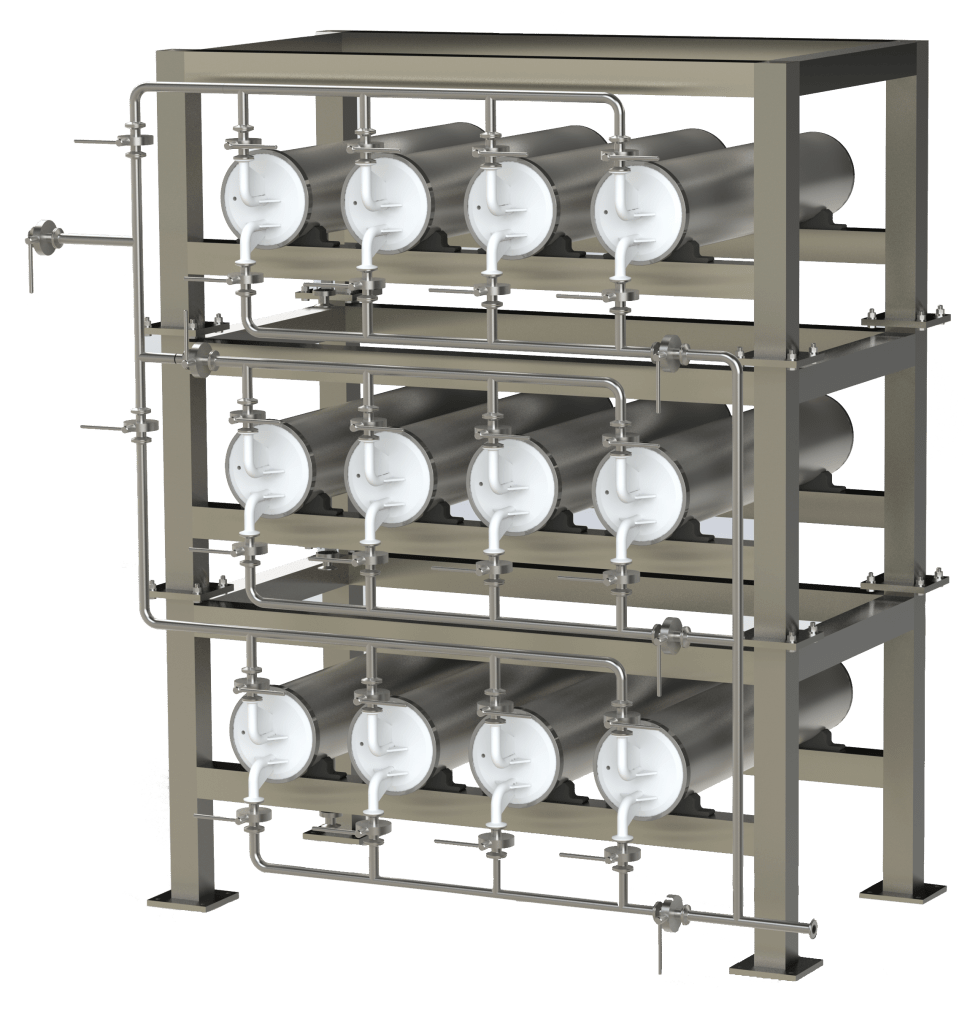

MAGNEXFLO Automatic filtration system with regeneration of filtering elements

MAGNEXFLO is the filtration system designed by BEA Technologies, generated by a long experience in filtration processes that represents the solutions for many food, biological and fine chemical companies producing viscous and gelatinous products. The system is modular and can be fitted to satisfy the requirements of each user; it is engineered to work even in fully automatic mode to guarantee the quality of filtered product and to reduce the need of specialized workforce to manage it.