INDUSTRY

Filters and Filtration Systems

BEA Technologies provides solutions for filtration of liquids and compressed gases designed for the requirements of different industries:

- Mechanical

- Chemical

- automotive and railways

- textile

- Chemical

- Inks, paints and coatings

- Energy production

- Environmental protection and plastic recycling.

The knowledge in specific applications as filtration of chemical products, solvents and colorants, the protection to heat exchangers, filtration of water in cooling towers and closed loops, condensate treatment has allowed to develop high performance filters in compliance with typical requirements of industry, laboratories and technical assistance.

CHEMICAL INDUSTRY

- Filtration of intermediate and reaction products

- Purification of aggressive fluids and solvents

- Stabilization to prevent growth of microorganism

- Filtration of cooling water and utilities management (including treatment of compressed gases and steam)

- Removal of solid particles from waste water before delivery to biological treatment

- Tank venting

INKS AND COATINGS

- Filtration of water based coatings

- Filtration of solvent based coatings

- Purifications of ink-jet and inks for printing

- Compressed air and gas treatment

MECHANICAL INDUSTRY

- Filtration of make-up and cooling water

- Clarification of mineral and hydraulic oils

- Filtration of fuels

- Filtration of cleaning and degreasing solutions

- Compressed air and gas treatment

AUTOMOTIVE

- Filtration of coating

- Cleaning of cooling solutions for welding equipment

- Filtrazione of cooling water

TEXTILE INDUSTRY

- Compressed air and gas treatment

- Filtration of cooling and make-up water

ENERGY PRODUCTION

- Filtration for protection of reverse osmosis plants

- Purification of condensates

- Filtration of make-up and cooling water

- Treatment of steam

ENVIROMENTAL PROTECTION

Filtration of plastic particles from process fluids

Separation of inorganic sediments from recycled plastics

Filter vessels and housing are manufactured in compliance with following codes and regulations:

- PED – ASME codes for pressure vessels and housings

- ATEX – for filtration equipment installed in hazardous industrial areas

- Production of filtering systems, pressure vessels and metal structures

- Recognition for BV MODE II Scheme for filters

- Qualified technical assistance

- Stock of spare parts ready for delivery

- Capability to execute filtration test in internal laboratory and on customer’s site to size and optimize filtration process

- Customer service can answer any technical and commercial query

MAGNEXFLO: AUTOMATIC FILTRATION SYSTEMS

The MAGNEXFLO filtration system designed by BEA Technologies comes from a deep experience in this field and represents the solution for many products that are difficult to clarify, combining the filtration action with the automation that controls the REGENERATION process of the filtered elements. The dimensions of the MAGNEX Filtration element, which has the ability to retain a large amount of contaminants and colloidal particles, can be easily regenerated that represents the specific feature of the system.

FILTROMATIC

The FILTROMATIC series of Automatic Self-cleaning Filters incorporate the specific design and application experience of BEA Technologies for clarification of water flow rates from 20 m3/h to 10.000 m3/h with filtration ratings from 50 to 2000 micron.

FILTROMATIC is designed for 24 /24 hours continuous service for 365 days/year due to the robustness of construction and high operative reliability of these filters.

Backwashing is automatically controlled, while the FILTROMATIC continues the filtration, with minimal loss of water for filter regeneration.

The AL series represents the ideal solution for filtration of fresh water, industrial process water and aqueous liquids, while AM series is dedicated for filtration of sea water and brackish water.

SM series is dedicated to relatively small flow rates.

All FILTROMATIC filters of AL, AM and SM series comply with CE regulations and can be manufactured according to ASME code.

FLOWMATIC

The automatic self-cleaning filter Type FLOWMATIC is designed to remove solid and sand particles from river and sea water used for cooling or industrial purposes.

The filter is manufactured with a filtration rating from 1000 to 3000 micron and is specifically indicated for the protection of heat exchangers because can operate 24/24 hours per day without local surveillance.

The flow rate of the water is guaranteed also when the filter is back-washing mode. The back-washing is started by a DP signal and controlled by a timer.

HYPERMATIC

THE AUTOMATIC SELF-CLEANING FILTER TYPE HYPERMATIC IS DESIGNED TO FILTER UP TO 25 MICRON.

HYPERMATIC filter is characterized by the specific design of the filter element which prevent the compaction of retained contaminants and allow to obtain a removal rating up to 25 micron.

During regeneration cycle of Hypermatic filter, the service is not stopped and filtration continues because only a minimal quantity of filtered water is used for cleaning of filter element.

The filter is simple but fully automatic, with a robust construction and fitted to work in remote areas without control.

The main characteristic is represented by the filtration with a rating up to 25 micron, without the need to replace the filter element on a periodical basis.

HIGH EFFICIENCY FILTRATION OF CRITICAL PRODUCTS

As regulations on the quality of many fluids and liquids used by heavy-duty and light industries become more strict, BEA Technologies can provide high performance filters across the entire process spectrum which need to produce under High critical specifications.

BEA Technologies can advise you about the best filtration products able to give a solution to your quality challenges and make you comply with more strict process requirements impacting on oil producers, polymer manufacturers, lubricants blenders, additive manufacturers, chemical solutions and sanitizers, technical gas and original equipment manufacturers.

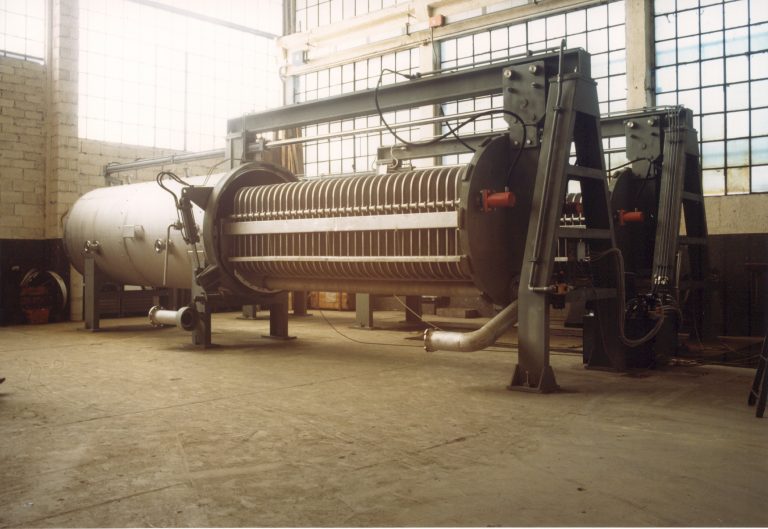

BEA “UNYVER” PRECOAT PRESSURE LEAF FILTERS

BEA “UNYVER” series are vertical and horizontal leaf filters that have a very high filtration area.

They are recommended for the filtration of liquids with medium-high content of solids with fouling effect and where the cake of solid particles must be recovered in dry form for disposal.

Filter’s leaves are vertically mounted and kept in parallel by spacers; the filtrate is collected by the manifold which supports the leaves and the cake is discharged through a large drain butterfly valve.

Our proposal can include single filters or complete package of leaf filters, precoat and feed pumps, precoat tank and dosing systems.