BEA Technologies informs our valued customers that a different packaging and MARKING methodology has been introduced for the polyethylene wrapping of the filter elements, thanks to the commissioning of a new machine acquired as part of planned investments to increase the production capacity of the entire sector dedicated to microfiltration filter elements.

The new equipment with an automated cycle, allows for speeding up the packaging process and consequently contributes to improving delivery times.

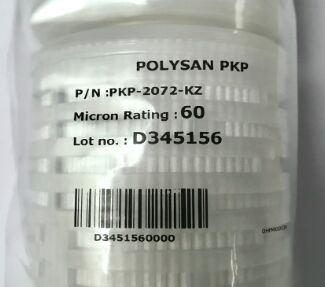

BEA Technologies, to pursue the reduction of environmental impact, plans to eliminate paper labels and instead implement direct stamping on the polyethylene wrapping. This change aims to simplify the recycling of

polyethylene bags.

It is important to highlight that the composition of materials that come into contact with the filtering elements during packaging, specifically food-grade polyethylene, remains unchanged. The current packaging method will remain in effect to ensure greater production flexibility.

Our dedicated commercial team is available for further inquiries or clarifications.

Attached is an example of LASER marking applied to the bags of our microfiltration filter elements.